Introduction

The Methylparaben Production Process with Cost Analysis is an essential report for stakeholders in the pharmaceutical, cosmetic, and food industries. This report provides a thorough examination of the methylparaben production process, highlighting the cost structures and offering insights to help businesses optimize their operations and enhance profitability. Understanding the intricacies of the production process, market drivers, raw material requirements, and associated costs is crucial for companies looking to maintain a competitive edge in this dynamic market.

Request Free Sample – https://www.procurementresource.com/production-cost-report-store/methylparaben/request-sample

Procurement Resource Assessment of the Methylparaben Production Process

Procurement Resource offers a comprehensive assessment of the Methylparaben Production Process, covering every critical aspect from raw material procurement to final product delivery. This assessment includes detailed insights into production methodologies, cost structures, and efficiency optimization strategies. By leveraging this assessment, businesses can gain a clear understanding of the factors influencing production costs and identify opportunities for cost reduction and process improvement.

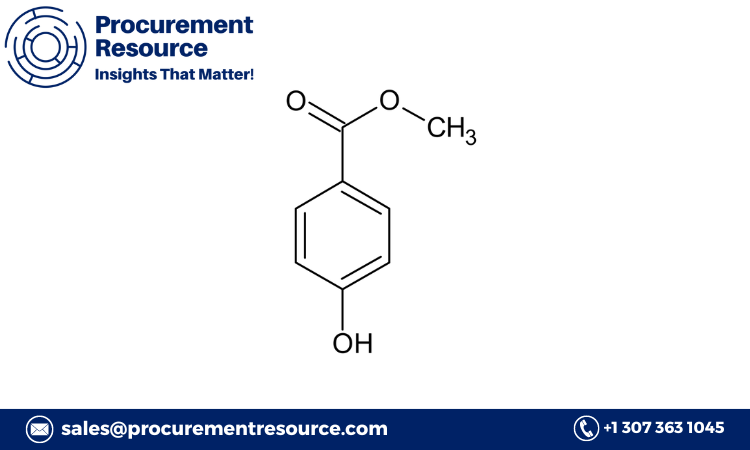

Understanding Methylparaben

Methylparaben is a widely used preservative in the pharmaceutical, cosmetic, and food industries due to its effective antimicrobial properties. It is a type of paraben, which is a class of chemicals commonly used to prevent the growth of harmful bacteria and mold, thereby extending the shelf life of products. Methylparaben is valued for its safety, efficacy, and versatility, making it a critical ingredient in a variety of consumer products, including skincare items, shampoos, makeup, and processed foods.

Market Drivers

Several factors drive the demand for methylparaben in the global market:

-

Growing Demand for Personal Care Products: The increasing consumer awareness about hygiene and skincare drives the demand for personal care products that incorporate preservatives like methylparaben to ensure product safety and longevity.

-

Expanding Pharmaceutical Industry: Methylparaben is extensively used as a preservative in pharmaceuticals to maintain the stability and efficacy of medications. The growth of the pharmaceutical industry, driven by rising healthcare needs, supports market demand.

-

Food Industry Applications: Methylparaben is used as a preservative in the food industry to extend the shelf life of processed foods. The growing demand for convenience foods and ready-to-eat products fuels its use.

-

Regulatory Approvals: The acceptance and regulatory approvals of methylparaben by health authorities such as the FDA and EFSA ensure its continued use in various products, driving market growth.

Raw Materials Requirements

The production of methylparaben requires specific raw materials, including:

-

Para-Hydroxybenzoic Acid (PHBA): The primary raw material for methylparaben production is para-hydroxybenzoic acid, which undergoes esterification to form methylparaben. The quality and availability of PHBA are crucial for efficient production.

-

Methanol: Methanol is used as a reactant in the esterification process to produce methylparaben. The purity and cost of methanol impact the production process.

-

Catalysts and Solvents: Various catalysts and solvents are used to facilitate the esterification reaction. The selection and optimization of these components are vital for maximizing yield and efficiency.

Costs and Key Process Information

Understanding the costs and key process information is essential for optimizing the methylparaben production process. This includes:

-

Raw Material Costs: The cost of procuring PHBA, methanol, and catalysts forms a significant portion of the overall production cost. Fluctuations in the prices of these raw materials can directly impact the cost-effectiveness of the production process.

-

Energy Consumption: Methylparaben production involves energy-intensive processes such as heating, mixing, and purification. Monitoring and optimizing energy consumption can lead to substantial cost savings and improved process efficiency.

-

Labor and Overheads: The cost of skilled labor and overhead expenses, including maintenance, quality control, and safety measures, contribute to the total production cost. Implementing automation and process optimization can help reduce labor costs and enhance productivity.

-

Waste Management: The production of methylparaben generates waste by-products that need to be managed and disposed of according to environmental regulations. Effective waste management practices can minimize environmental impact and associated costs.

Looking for an Exhaustive and Personalized Report?

Are you looking for an exhaustive and personalized report that could significantly substantiate your business? Procurement Resource offers tailored reports that provide in-depth analysis and insights specific to your business needs. These reports cover all aspects of the methylparaben production process, from raw material procurement to final product delivery, helping you make informed decisions and achieve cost efficiencies.

Our personalized reports include:

- Customized Cost Analysis: Detailed breakdown of production costs tailored to your specific production setup and operational parameters.

- Process Optimization Recommendations: Expert recommendations for improving process efficiency, reducing waste, and minimizing costs.

- Market Analysis and Forecasts: Comprehensive analysis of market trends, demand drivers, and future growth projections to help you stay ahead of the competition.

- Regulatory Compliance Guidance: Information on relevant environmental and safety regulations to ensure your production processes are compliant and sustainable.

Conclusion

The Methylparaben Production Process with Cost Analysis report by Procurement Resource is an invaluable resource for businesses operating in the pharmaceutical, cosmetic, and food industries. By understanding the production process, market drivers, raw material requirements, and associated costs, companies can optimize their operations and improve profitability. Whether you are looking to enhance your existing production processes or explore new opportunities in the methylparaben market, this comprehensive report provides the insights and guidance you need to succeed.

In conclusion, this report is an indispensable tool for industry stakeholders. By understanding the factors influencing production costs and leveraging process optimization strategies, businesses can achieve significant cost savings and operational efficiencies. Staying updated with the latest market trends and regulatory requirements will enable stakeholders to navigate the complexities of the methylparaben market and maintain a competitive edge.

Whether you are a seasoned industry player or a new entrant, the Methylparaben Production Process with Cost Analysis report is your key to unlocking the full potential of the methylparaben market.