In today’s competitive market, packaging plays a crucial role in capturing the attention of consumers. Advanced printing methods can significantly enhance the aesthetic appeal and functionality of box design, making products stand out on the shelves. One of the most discussed techniques in this realm is the comparison of debossing vs embossing. This article explores various advanced printing methods and their impact on box design.

Understanding Debossed vs Embossed

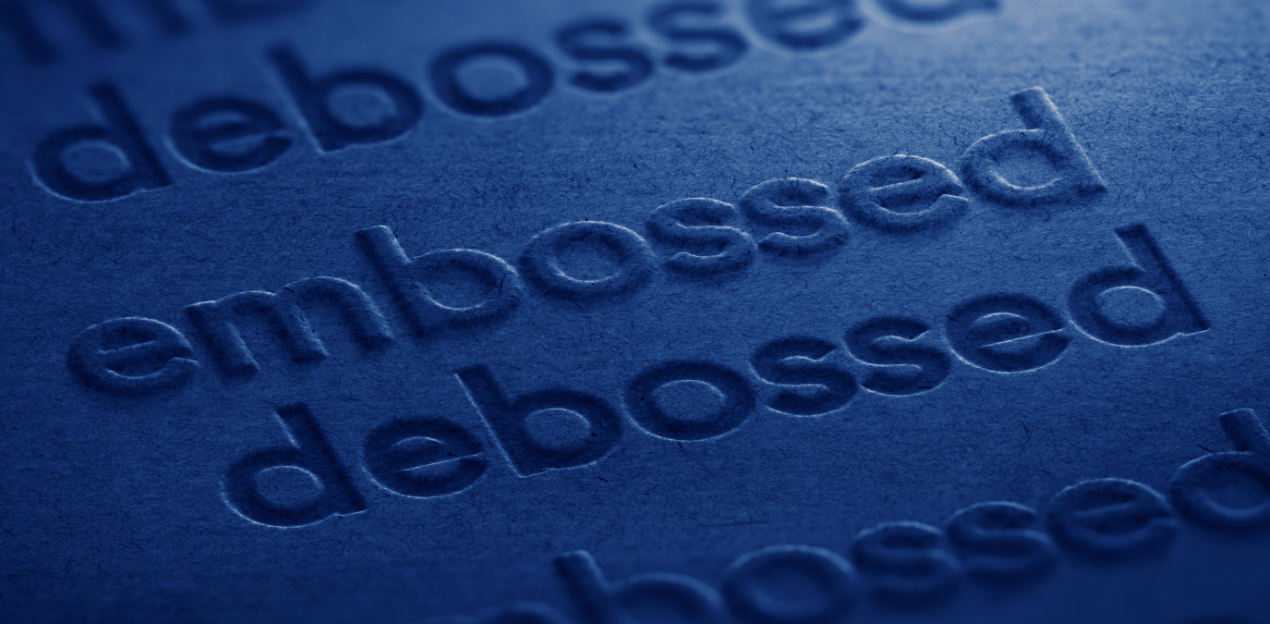

Debossing and embossing are popular techniques used to create raised or recessed designs on packaging materials. Embossing raises the design above the surface, while debossing creates an indented effect. Both techniques add a tactile element to the packaging, making it more engaging for consumers. When choosing between debossing and embossing, consider the desired effect and the material of the box. Embossing tends to stand out more and can highlight logos or important text, while debossing offers a subtler, yet equally elegant look.

The Role of Digital Printing in Box Design

Digital printing has revolutionized the packaging industry by offering high-quality, cost-effective solutions for small to medium print runs. This method allows for quick turnaround times and the ability to customize each box with unique designs, colors, and text. Digital printing is ideal for businesses looking to create limited edition packaging or personalized products. It also supports a wide range of materials, ensuring that the printed design maintains its quality and vibrancy.

The Impact of Offset Printing on Packaging

Offset printing is a traditional printing method that remains popular due to its ability to produce sharp and consistent images. This technique is particularly beneficial for large print runs, as it reduces costs while maintaining high quality. Offset printing uses metal plates to transfer ink onto the packaging material, allowing for precise color reproduction and fine details. It is suitable for complex designs that require a high level of accuracy and consistency.

Exploring Flexographic Printing for Box Design

Flexographic printing, or flexo printing, is known for its versatility and efficiency. This method uses flexible plates to print on a variety of substrates, including cardboard, plastic, and metallic foils. Flexographic printing is ideal for high-volume production and can accommodate a wide range of inks, including water-based, solvent-based, and UV-curable inks. This makes it a popular choice for packaging that needs to be both durable and visually appealing.

The Advantages of UV Printing in Packaging

UV printing uses ultraviolet light to cure or dry the ink as it is printed. This results in vibrant colors and a glossy finish that can enhance the visual appeal of the packaging. UV printing is particularly effective for adding special effects, such as spot varnishes, metallic inks, and textures. This method also offers excellent adhesion to a variety of materials, making it suitable for complex box designs that require a high-quality finish.

Screen Printing for Custom Packaging

Screen printing, also known as silk screening, involves pushing ink through a stencil or screen to create a design on the packaging material. This method is highly versatile and can be used on a wide range of surfaces, including paper, plastic, and metal. Screen printing is ideal for creating bold, vibrant designs with high opacity. It is also suitable for producing special effects, such as glitter or raised inks, which can add a unique touch to the packaging.

Enhancing Box Design with Hot Foil Stamping

Hot foil stamping is a technique that uses heat and pressure to apply metallic foil to the packaging material. This method can create stunning visual effects, such as shiny or matte finishes, holographic patterns, and embossed textures. Hot foil stamping is often used to highlight logos, brand names, and other important elements of the packaging. It adds a premium look and feel to the box, making it more attractive to consumers.

The Use of Gravure Printing in Packaging

Gravure printing, or rotogravure printing, is a high-quality printing method that uses engraved cylinders to transfer ink onto the packaging material. This technique is known for its ability to produce fine details and rich, consistent colors. Gravure printing is ideal for long print runs and is commonly used for flexible packaging, labels, and wrapping materials. It offers excellent color depth and durability, making it suitable for high-end products.

Integrating Sustainable Printing Practices

As consumers become more environmentally conscious, the demand for sustainable packaging solutions is growing. Advanced printing methods can be integrated with sustainable practices to reduce the environmental impact of packaging. This includes using eco-friendly inks, such as vegetable-based or water-based inks, and recyclable or biodegradable materials. By adopting sustainable printing practices, businesses can create attractive and eco-friendly packaging that appeals to environmentally conscious consumers.

Future Trends in Advanced Printing for Box Design

The future of box design lies in the continued innovation of advanced printing methods. Technologies such as digital printing and 3D printing are expected to play a significant role in the development of new packaging solutions. These methods offer greater customization and flexibility, allowing businesses to create unique and engaging packaging designs. Additionally, advancements in sustainable printing practices will further drive the adoption of eco-friendly packaging solutions. As the industry evolves, businesses that embrace these trends will be well-positioned to meet the changing demands of consumers and stand out in the market.

Conclusion

In conclusion, advanced printing methods such as debossing, embossing, digital printing, offset printing, flexographic printing, UV printing, screen printing, hot foil stamping, and gravure printing offer a multitude of benefits for enhancing box design. By leveraging these techniques, businesses can create visually appealing and functional packaging that attracts consumers and adds value to their products. As the market continues to evolve, staying up-to-date with the latest printing technologies and sustainable practices will be crucial for success.

Read more at: rankmywork.com