Introduction

Toluene Thiol Production Process with Cost Analysis is increasingly important as industries seek to optimize their chemical production processes. This press release provides a comprehensive assessment of the toluene thiol production process, examining market drivers, raw materials requirements, costs, and key process information, offering an exhaustive and personalized report that can substantially support your business.

Request Free Sample – https://www.procurementresource.com/production-cost-report-store/toluene-thiol/request-sample

Procurement Resource Assessment of Toluene Thiol Production Process

Procurement Resource offers a detailed assessment of the toluene thiol production process, providing insights into each stage from raw material procurement to the final product. This assessment includes:

-

Raw Material Procurement: Securing high-quality raw materials is the first crucial step. The primary raw materials for toluene thiol production are toluene and hydrogen sulfide. Ensuring a reliable supply chain for these inputs is vital for uninterrupted production.

-

Chemical Synthesis: The synthesis process involves the reaction of toluene with hydrogen sulfide in the presence of a catalyst. This reaction produces toluene thiol, which is then separated and purified.

-

Purification and Quality Control: The crude toluene thiol undergoes purification to remove any impurities. Quality control measures are implemented throughout the process to ensure the final product meets industry standards.

-

Packaging and Distribution: The purified toluene thiol is then packaged and prepared for distribution to various industries.

This detailed assessment helps businesses understand the complexities of the production process, allowing them to optimize operations and improve efficiency.

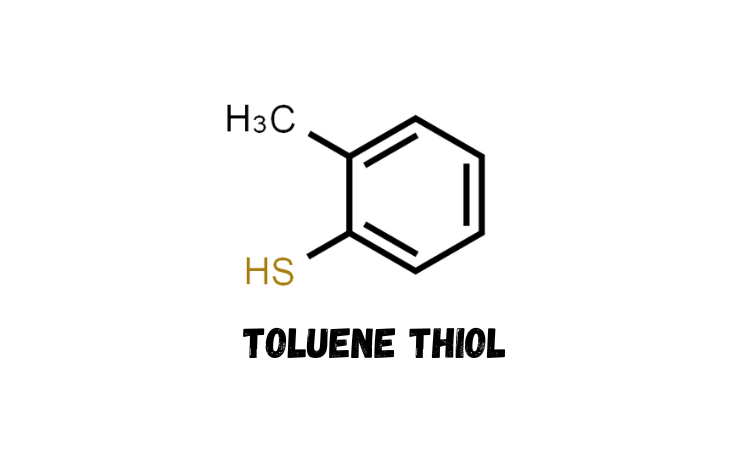

Understanding Toluene Thiol

Toluene thiol, also known as toluene mercaptan, is a colorless to pale yellow liquid with a strong odor. It is primarily used as an intermediate in the production of various chemicals, including pesticides, pharmaceuticals, and rubber chemicals. Toluene thiol is valued for its high reactivity and ability to form strong bonds with metals, making it an essential component in many industrial applications.

Key uses of toluene thiol include:

-

Chemical Manufacturing: Used as a building block in the synthesis of other chemicals.

-

Pharmaceuticals: Employed in the production of certain drugs and therapeutic agents.

-

Rubber Industry: Acts as a vulcanization agent, enhancing the properties of rubber.

Understanding the properties and applications of toluene thiol is essential for businesses involved in its production and use.

Market Drivers

Several market drivers are influencing the growth and demand for toluene thiol:

-

Industrial Demand: The demand for toluene thiol is driven by its extensive use in chemical manufacturing, pharmaceuticals, and the rubber industry. Growth in these sectors directly impacts the demand for toluene thiol.

-

Technological Advancements: Advances in chemical synthesis and production technologies have improved the efficiency and yield of toluene thiol production, driving down costs and increasing availability.

-

Environmental Regulations: Stringent environmental regulations and the need for cleaner production processes have led to increased demand for efficient chemical intermediates like toluene thiol.

-

Global Economic Growth: Economic growth in emerging markets is boosting industrial activities, thereby increasing the demand for chemicals, including toluene thiol.

These market drivers are creating opportunities for businesses to expand their production capabilities and meet growing demand.

Raw Materials Requirements

The primary raw materials required for the production of toluene thiol are:

-

Toluene: A colorless, water-insoluble liquid commonly used as an industrial feedstock. It is derived from crude oil and natural gas.

-

Hydrogen Sulfide: A colorless, toxic gas with a distinct odor of rotten eggs. It is used in various chemical processes and can be sourced from natural gas and petroleum refining.

Securing a consistent and high-quality supply of these raw materials is crucial for the efficient production of toluene thiol. Proper handling and storage of these materials are also essential to ensure safety and quality.

Costs and Key Process Information

A detailed cost analysis of the toluene thiol production process involves several key components:

-

Raw Material Costs: The cost of procuring toluene and hydrogen sulfide forms a significant portion of the overall production cost. Fluctuations in the prices of these raw materials can impact the production costs.

-

Production Costs: These include expenses related to chemical synthesis, such as energy consumption, catalyst costs, and labor. Advanced production technologies can help reduce these costs by improving efficiency and yield.

-

Purification and Quality Control Costs: Ensuring the purity and quality of the final product involves additional costs for purification processes and quality control measures.

-

Capital and Operational Costs: Initial investments in production facilities and ongoing operational costs for maintenance and workforce.

Key process information includes the reaction conditions, such as temperature, pressure, and catalyst used, as well as the efficiency and yield of the production process. Optimizing these parameters can lead to significant cost savings and improved production efficiency.

Looking for an Exhaustive and Personalized Report?

For businesses seeking a comprehensive and personalized report on the toluene thiol production process, Procurement Resource offers detailed market insights, cost analysis, and process optimization recommendations. Our reports are tailored to meet the specific needs of your business, providing you with:

-

In-depth Market Analysis: Detailed analysis of market trends, drivers, and opportunities for toluene thiol.

-

Cost Breakdown: Comprehensive breakdown of costs involved in the toluene thiol production process, including raw material costs, processing costs, and operational costs.

-

Process Optimization: Recommendations for optimizing the production process to enhance efficiency, reduce costs, and improve product quality.

-

Regulatory Compliance: Insights into regulatory requirements and compliance measures for producing toluene thiol.

Our exhaustive reports are designed to provide you with the information and insights you need to make informed decisions, enhance your operations, and achieve your business goals.

Conclusion

Understanding the toluene thiol production process with cost analysis is crucial for businesses operating in the chemical industry. By analyzing the production process, conducting thorough cost analysis, and optimizing key process parameters, businesses can enhance their operations and meet growing market demand. For an exhaustive and personalized report that could significantly substantiate your business, contact Procurement Resource today and take the first step towards operational excellence and sustainability.

About Us:

Procurement Resource is an invaluable partner for businesses seeking comprehensive market research and strategic insights across a spectrum of industries. With a repository of over 500 chemicals, commodities, and utilities, updated regularly, they offer a cost-effective solution for diverse procurement needs. Their team of seasoned analysts conducts thorough research, delivering clients with up-to-date market reports, cost models, price analysis, and category insights.

By tracking prices and production costs across various goods and commodities, Procurement Resource ensures clients receive the latest and most reliable data. Collaborating with procurement teams across industries, they provide real-time facts and pioneering practices to streamline procurement processes and enable informed decision-making. Procurement Resource empowers clients to navigate complex supply chains, understand industry trends, and develop strategies for sustainable growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: [email protected]

Toll-Free Number: USA Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA