Ductwork supplies refer to the materials and components used in the construction and installation of HVAC (Heating, Ventilation, and Air Conditioning) duct systems. These supplies are crucial for ensuring efficient airflow, maintaining indoor air quality, and regulating temperature in residential, commercial, and industrial buildings. Let’s explore the essential components and functions of ductwork supplies in detail.

Components of Ductwork Supplies

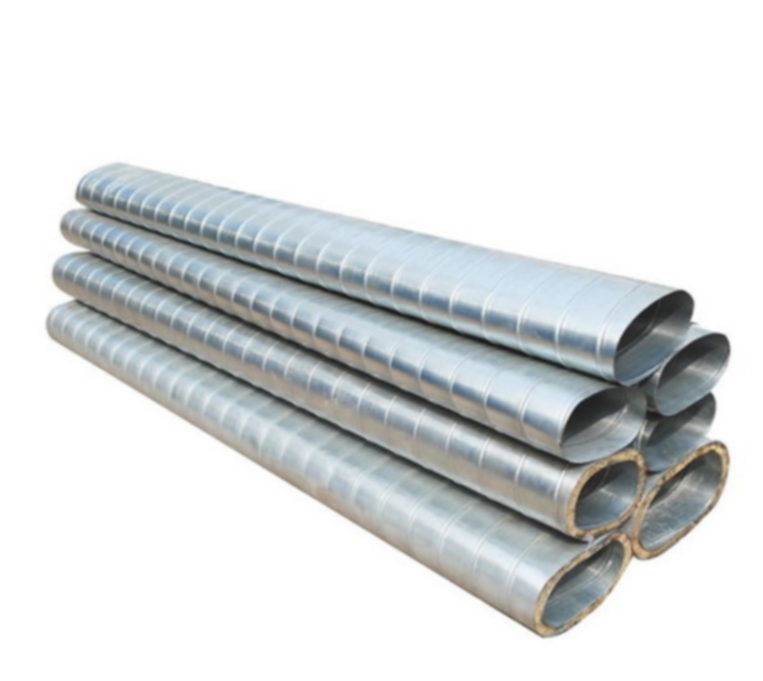

Ducts:

Ducts are the main channels through which air flows. They are typically made from materials like galvanized steel, aluminum, fiberglass, or flexible plastic. The choice of material depends on factors such as cost, durability, and the specific requirements of the HVAC system.

Fittings:

Fittings include elbows, tees, reducers, and dampers. Elbows allow ducts to change direction smoothly, tees divide airflow into multiple directions, reducers transition between different duct sizes, and dampers control airflow by adjusting the volume of air passing through.

Registers and Grilles:

Registers are equipped with adjustable louvers or dampers to control airflow direction and volume. Grilles cover duct openings and come in various designs to enhance air distribution while maintaining aesthetic appeal.

Duct Insulation:

Insulation materials like fiberglass or foam board wrap around ducts to reduce heat loss or gain during air transport. Proper insulation improves energy efficiency and prevents condensation buildup.

Sealants and Adhesives:

These materials are crucial for sealing joints between duct sections, fittings, and connections. They prevent air leakage, which can lead to energy loss and decreased HVAC system efficiency.

Supports and Hangers:

Supports such as straps, hangers, and brackets secure ducts in place within the building structure. Proper support prevents sagging, which can restrict airflow and cause system inefficiencies.

Access Doors:

Access doors provide entry points for maintenance personnel to inspect and clean ducts, ensuring optimal system performance and air quality.

Functions of Ductwork Supplies

Air Distribution:

The primary function of ductwork supplies is to distribute conditioned air from HVAC systems to different areas within a building. Properly designed ductwork ensures even airflow distribution, maintaining consistent indoor comfort levels.

Ventilation:

Ductwork supplies facilitate the exchange of indoor and outdoor air, ensuring adequate ventilation to remove pollutants, odors, and excess moisture from indoor spaces.

Temperature Control:

By transporting heated or cooled air, ductwork supplies help regulate indoor temperatures according to building occupants’ comfort requirements and seasonal weather conditions.

Energy Efficiency:

Well-designed ductwork, along with insulated ducts and sealed joints, improves HVAC system efficiency by minimizing air leakage and reducing energy consumption.

Air Quality Maintenance:

Filters installed within ductwork capture dust, allergens, and other particles, improving indoor air quality and creating a healthier environment for building occupants.

Noise Reduction:

Properly installed ductwork with sound attenuators and insulated ducts helps reduce noise transmission from HVAC systems, ensuring a quieter indoor environment.

System Durability and Maintenance:

Ductwork supplies, when installed correctly and maintained regularly, contribute to the longevity of HVAC systems. This reduces the frequency of repairs and replacements, thus lowering operational costs over time.

If you want to shop online then visit company website and Order Now.

Conclusion

Ductwork supplies play a critical role in the performance and efficiency of HVAC systems. By understanding their components and functions, HVAC professionals can design, install, and maintain ductwork that meets the specific needs of residential, commercial, and industrial buildings. Choosing high-quality materials, proper insulation, effective sealing, and adequate support ensures optimal airflow, energy efficiency, indoor air quality, and overall comfort for building occupants. As technology advances, new materials and design innovations continue to enhance the effectiveness and sustainability of ductwork supplies in modern HVAC applications.