Hermetically Sealed Transformers are electrical transformers designed to be completely airtight and watertight. This type of transformer is constructed to prevent the ingress of air, moisture, and contaminants, which can degrade the insulation and lead to failures. Here are some Types, key characteristics and benefits of hermetically sealed transformers.

Types of Hermetically Sealed Transformers

Hermetically sealed transformers come in various types, each designed to meet specific needs and applications. Here are some of the main types:

1. Oil-Immersed Hermetically Sealed Transformers

These are the most common types of hermetically sealed transformers, where the transformer core and windings are immersed in oil. The oil acts as an insulator and coolant.

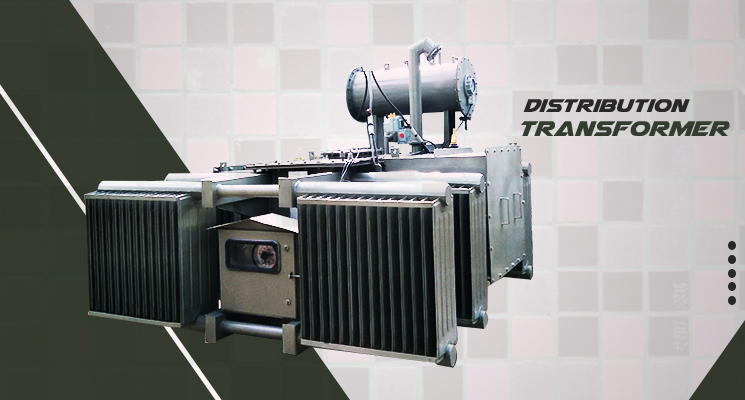

Distribution Transformers: Used in electrical distribution networks to step down the voltage for use in residential, commercial, and industrial applications.

Power Transformers: Used in transmission networks to step up or down voltages in power generation and distribution systems.

2. Dry-Type Hermetically Sealed Transformers

These transformers do not use oil for insulation or cooling. Instead, they rely on air or other insulating materials and are sealed to prevent the ingress of contaminants.

Cast Resin Transformers: The windings are encapsulated in epoxy resin, providing excellent protection against moisture and dust. Suitable for indoor and outdoor applications.

Vacuum Pressure Impregnated (VPI) Transformers: The windings are impregnated with resin under vacuum pressure, offering high electrical and mechanical strength.

3. Hermetically Sealed Instrument Transformers

These transformers are used to measure electrical quantities such as current and voltage, and they are designed to be airtight to ensure accuracy and reliability.

Current Transformers (CTs): Used to measure high currents by producing a lower, proportional current that can be safely measured by instruments.

Voltage Transformers (VTs) or Potential Transformers (PTs): Used to measure high voltages by producing a lower, proportional voltage that can be safely measured by instruments.

4. Hermetically Sealed Specialty Transformers

These are designed for specific applications and environments.

Marine Transformers: Designed to withstand the harsh conditions of marine environments, including exposure to saltwater and high humidity.

Underground Transformers: Used in underground installations where space is limited, and protection from moisture and contaminants is critical.

Renewable Energy Transformers: Tailored for renewable energy applications such as wind turbines and solar power plants, where they must endure varying weather conditions.

5. Hermetically Sealed Autotransformers

These transformers have a single winding that acts as both primary and secondary winding, with a portion of the winding shared between them. They are sealed to prevent contamination and are used in applications where voltage regulation is needed.

Characteristics of Hermetically Sealed Transformers:

Sealed Construction: The transformer is fully enclosed in a tank that is sealed from the external environment. This can be achieved using a variety of sealing methods, including welded seams and gasket flanges.

Oil-Filled: These transformers are often filled with insulating oil, which serves to cool the transformer and provide electrical insulation. The oil is sealed within the transformer tank.

No Breather System: Unlike conventional transformers that may have a breather system to allow for the expansion and contraction of air, hermetically sealed transformers do not have this system. Instead, they accommodate oil expansion through flexible membranes or bellows.

Corrosion Resistance: The external surfaces of the transformer are typically coated or made from materials that resist corrosion, ensuring a long service life even in harsh environments.

Benefits of Hermetically Sealed Transformers:

Enhanced Reliability: By preventing the ingress of moisture and contaminants, hermetically sealed transformers have higher reliability and longer service lives.

Low Maintenance: These transformers require less maintenance compared to conventional transformers because there is no need to monitor and replace silica gel breathers or regularly check for oil contamination.

Suitable for Harsh Environments: Hermetically sealed transformers are ideal for use in environments with high humidity, dust, salt, or other contaminants, such as coastal areas, underground installations, and industrial sites.

Reduced Risk of Oil Leakage: The sealed design minimizes the risk of oil leaks, which can be a significant environmental and fire hazard.

Enhanced Protection: The sealing ensures that the transformer components are protected from environmental factors.

Longevity: Reduced risk of contamination and degradation leads to a longer service life.

Maintenance-Free: Hermetically sealed designs typically require less maintenance compared to conventional transformers.

Each type of hermetically sealed transformer is chosen based on specific operational requirements and environmental conditions, ensuring optimal performance and reliability in their respective applications.

Hermetically sealed transformers are gaining attention as the future of application due to several key advantages they offer over traditional transformers. Here are some reasons why they are considered beneficial:

Applications of Hermetically Sealed Transformers:

Industrial Facilities: Where robust and reliable power distribution is needed in challenging conditions.

Renewable Energy Installations: Such as wind farms and solar power plants, where equipment must withstand outdoor environmental factors.

Underground and Submarine Cables: Where transformers are exposed to high levels of moisture.

Military and Defense: Where durability and reliability in various environmental conditions are critical.

Overall, hermetically sealed transformers are chosen for their durability, low maintenance, and suitability for harsh operating conditions.

Advantages of Hermetically Sealed Transformers:

1. Enhanced Protection and Durability

Moisture and Contaminant Resistance: Hermetically sealed transformers are completely sealed off from the external environment, preventing moisture, dust, and other contaminants from entering. This significantly reduces the risk of insulation degradation and corrosion, enhancing the longevity and reliability of the transformer.

Robust Construction: The sealed design makes these transformers highly resistant to extreme environmental conditions, including harsh weather, chemical exposure, and submersion in water.

2. Maintenance and Operational Efficiency

Low Maintenance: Due to their sealed nature, these transformers require less maintenance compared to conventional transformers. There is no need for regular checks and replacements of desiccants or regular inspections for contamination.

Reduced Downtime: With fewer maintenance requirements and higher durability, hermetically sealed transformers experience less downtime, ensuring continuous and efficient operation.

3. Safety and Environmental Considerations

Enhanced Safety: Hermetic sealing provides an extra layer of safety by containing any potential internal faults or failures, reducing the risk of oil leaks, fires, or explosions.

Eco-friendly: These transformers often use biodegradable and non-toxic insulation fluids, minimizing environmental impact. Their sealed design also prevents the release of insulating oil into the environment.

4. Performance and Efficiency

Improved Thermal Management: The hermetic seal helps in maintaining a stable internal environment, which can improve the thermal performance of the transformer. This leads to better efficiency and performance under varying load conditions.

Consistent Performance: With a controlled internal atmosphere, the electrical properties of the transformer remain stable, ensuring consistent performance over time.

5. Versatility and Application

Wide Range of Applications: Hermetically sealed transformers are suitable for a variety of applications, including industrial, commercial, and renewable energy systems. Their robust design makes them ideal for use in challenging environments, such as offshore platforms, underground installations, and remote locations.

Compact and Aesthetic Design: These transformers often have a more compact design, which can be beneficial for installations with space constraints. Their aesthetic appeal also makes them suitable for use in urban and residential areas.

Conclusion

The future of applications for hermetically sealed transformers is promising due to their enhanced protection, reduced maintenance, improved safety, and consistent performance. These advantages make them a reliable and efficient choice for modern electrical and industrial systems, aligning with the increasing demand for sustainable and robust power solutions.